India’s first blast furnace carbon capture plant supplied by Carbon Clean

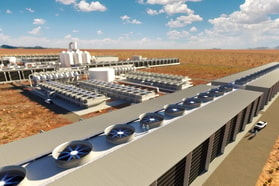

Carbon capture technology and service company Carbon Clean has provided India’s first carbon capture plant for a blast furnace, commissioned by steel giant Tata Steel.

Capable of capturing five tonnes of carbon dioxide (CO2) per day at Tata Steel’s Jamshedpur steel plant in India, CO2 is captured from the blast furnace gas into the modular skid mounted unit, allowing for reuse onsite of the captured gas.

Following the successful demonstration of the company’s project, Aniruddha Sharma, CEO, Carbon Clean, said that they are planning to rapidly accelerate the number of carbon capture projects.

... to continue reading you must be subscribed