Industry 4.0: Seeing is believing when it comes to future change

In the heart of Sheffield, UK lies a certain sense of industrial juxtaposition. On the one hand, the city’s manufacturing heritage is on full display with vistas of industrial buildings and reminders of the past at every corner. On the other, it is home to new clean technology (think electrolyser production for a hydrogen future) and smart manufacturing R&D facilities, pioneering a new industrial revolution.

At the forefront of this is the University of Sheffield Advanced Manufacturing Research Centre (AMRC), a network of world-leading research and innovation centres working with advanced manufacturing companies around the globe. The AMRC, part of the High Value Manufacturing Catapult, transforms industrial and economic performance by making step changes in productivity, increasing competitiveness, developing new products and processes, and training new talent and skills. Its 100-plus industrial members range from global giants like Boeing, Rolls-Royce, McLaren Automotive, BAE Systems and Airbus to small companies.

And herein lies a further sense of juxtaposition. Much of the pristine AMRC campus is located on the site of the old Orgreave coking plant, scene of one of the most violent industrial disputes in UK labour history, while its futuristic Factory 2050 site is built upon the site of the former Sheffield City Airport. These gleaming modern buildings and their ultra-clean interiors are the stage on which the transformation of the region’s traditional, and at times heavy industry, is being played out. Gleaming, minimalist floor space is home to experimental bays or workshops for testbed aviation production processes or new frontiers in milling and machining.

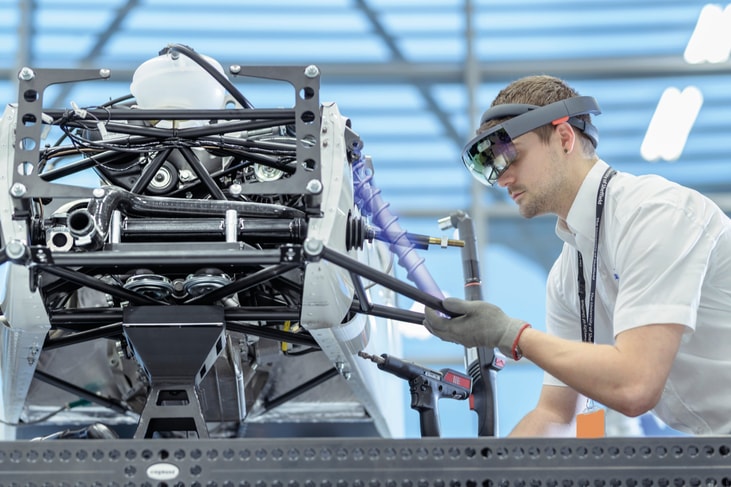

Seeing is most definitely believing when it comes to such state-of-the-art environments and technologies, and gasworld was privileged to tour the Factory 2050 site for itself earlier this year. The £43m facility, the UK’s first entirely dedicated to conducting collaborative research into reconfigurable robotic, digitally assisted assembly and machining technologies, is designed to address the rising need for high variation and mass customisation manufacturing throughout a diverse range of engineering sectors.

... to continue reading you must be subscribed