Plug Power: We must find a way to make hydrogen more accessible to the masses

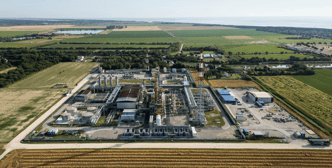

Described by CEO Andy Marsh as the “magic” inside any fuel cell, Plug Power revealed earlier this month it will begin production of its own membrane electrode assemblies (MEAs), a key component of the company’s new ProGen metal plate stack.

Leveraging the expertise gained through Plug Power’s acquisition of premier MEA technology developer American Fuel Cell (AFC), the new stack provides the US company with a competitive edge, doubling the power density of its graphite plate stack and extending the life cycle for on-road applications.

Plug Power begins production of MEAs

... to continue reading you must be subscribed