Japan’s Role in the Global Electronics Supply Chain

In this article, writers from The Gas Review (www.gasreview.co.jp), Japan’s premiere monthly news publication covering industrial gases and energy economics in Asia, share with us the ways in which the devastating earthquake and tsunami of March 11, 2011, affected the Japanese and global electronics industry and the supply of specialty gases used in electronics manufacturing.

Within Japan, many of the electronics gas users (mainly semiconductor manufacturers) are located inland, at a safe distance from the epicenter of the quake so disruption to most plants was limited. Two plants, Toshiba in Kitakami City, Iwate Prefecture (Pref.) and Renesas Electronics in Hitachinaka City, Ibaraki Pref., located near the region hardest hit by the quake, did suffer some damage. The factor that was most disruptive to the specialty gases supply chain and to electronics manufacturers was the lack of reliable power, a situation created by the after-effects of the earthquake and tsunami. For example, on-site nitrogen plants that supply semiconductor manufacturers were largely undamaged, but had to stop operation due to electric outages. They have since recovered to 70–80 percent of full operation.

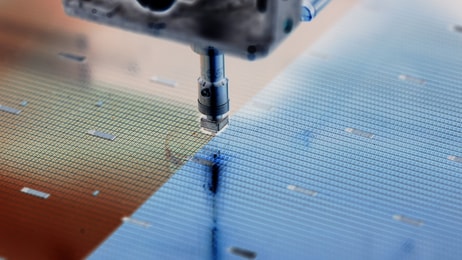

Gas Related Equipment

The demand for gas related equipment (bulbs, fittings, mass flow controllers, regulators, filters, pressure sensors, pipes, and tubes) for use with semiconductor manufacturing devices has not been seriously affected by the earthquake. Orders have remained at the same high level as during the same period the previous year. As 60–70 percent of overall demand for gas related equipment (and over 80 percent of demand for some kinds of equipment) comes from the overseas market, the earthquake did not adversely affect demand for these products. The main users of this equipment are the Korean firm Samsung Electronics and the Taiwanese firm Taiwan Semiconductor Manufacturing Company (TSMC). In Japan, a large equipment user is Toshiba’s Yokkaichi plant, which is located approximately 500 miles from the epicenter of the earthquake and was only shut down briefly.

Semiconductor Equipment Manufacturers

Among Japanese semiconductor manufacturing equipment producers the overall damage from the earthquake was also light. Tokyo Electron, the largest semiconductor manufacturing equipment producer, has three production centers: Tokyo Electron Tohoku in Iwate Pref., which is involved in heat treatment film formation; Tokyo Electron Technology Development Institute in Miyagi Pref.; and Tokyo Electron AT in Miyagi Pref., which is involved in producing etching equipment. All three facilities suffered little internal and external damage. According to their press release of March 17, essential services at Tokyo Electron Tohoku had been restored and operations were expected to be reestablished at the end of March or the beginning of April, including their Sendai and Matsushima plants. The ceremony for marking the establishment of Tokyo Electron’s new plant in Sendai was delayed by six months because of a fire that occurred on March 4, before the earthquake.

... to continue reading you must be subscribed