Join Cold Jet at the IMTS 2018 Conference

Tyson Marlowe, Vice-President Global Training and Development, Cold Jet, will be presenting the benefits of the innovative dry ice cleaning technology at IMTS 2018.

The presentation, ‘Reducing Waste with Non-Destructive, Environmentally Sustainable Dry Ice Cleaning’, will take place Monday 10th September from 3:15PM – 4:40PM in room W192-B at McCormick Place.

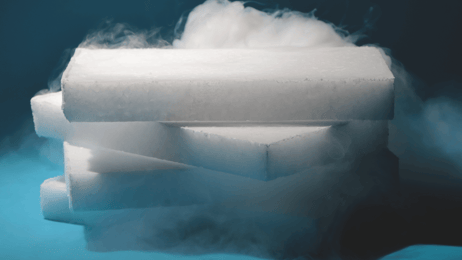

The presentation provides details on how dry ice cleaning, a non-abrasive and dry-cleaning solution, supports lean initiatives by cutting costs, waste and downtime. Dry ice cleaning maximises asset utilisation rates and asset life while eliminating secondary waste and the consequential downtime of traditional cleaning. Attendees will learn how dry ice cleaning allows production equipment to be cleaned in-place without time-consuming disassembly. The process can be used to remove production residues, release agents, contaminants, paints, oils and biofilms – and can be used for many general cleaning applications. It provides a quick, safe and economical solution to cleaning tooling and equipment. Using dry ice cleaning results in less downtime, a better clean, higher quality parts with lower scrap rates, improved tool utilisation and longer asset life. Participants will be able to determine how their production and quality can be improved and how the process affects the environment.

... to continue reading you must be subscribed