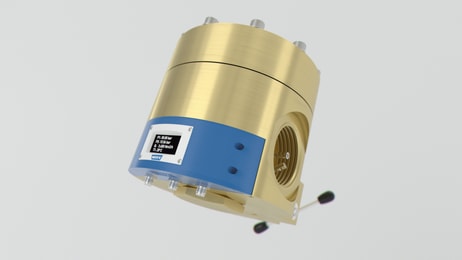

KNF Neuberger launches its new flow-tight liquid transfer pump

KNF Neuberger has introduced a new solenoid-driven FL 10 diaphragm pump for original equipment manufacturers (OEMs).

With a nominal liquid flow rate of 100 mL/min, FL 10 features bi-directional flow-tightness without additional check valves, IP 65 protection, simple linear flow rate adjustment and has a maintenance-free expected lifetime.

The FL 10 pump uses spring tension in the linear solenoid drive to keep it flow-tight in both directions when turned off, making additional check valves unnecessary and helping to reduce costs. Built for operation in demanding environments such as wet or dusty areas, the pump’s IP 65 protection class reduces the need for additional protection in the customer’s system. Furthermore, sealing between the pump housing and the linear drive ensures fail-safe operation, so that in case of a ruptured diaphragm, liquid is kept away from other areas of the system. Laser-welded head parts keep the pump leak-free.

... to continue reading you must be subscribed

![Atlas Copco_HP BOG[1]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/atlascopco_hpbog1_804720.png)

![Atlas Copco_HP BOG[1]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/atlascopco_hpbog1_804720.png)