Leybold’s energy efficient diffusion pumps

Vacuum supplier Leybold has significantly reduced the energy consumption of its DIP and newly developed DIJ diffusion pump series, with the aid of intelligent technologies and innovations.

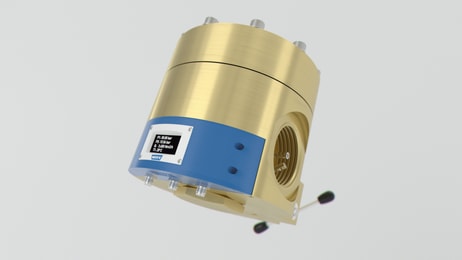

Leybold now provides a number of optimised models and accessories that are flexible and can be implemented worldwide into the relevant diffusion pump applications. The new DIJ family boasts an optimised housing design, offering connections for both ANSI flange and ISO flange components as well as various electrical connection variants. The new five-stage nozzle system of the DIJ series has been especially improved for the pressure range from 10-2 to 10-3 mbar.

Through design changes and modern control elements, the vacuum specialist was able to reduce the energy consumption of the diffusion pumps by an average of more than 30%, without sacrificing performance. In addition, there are further improvements in terms of serviceability and integration into the customers’ systems.

... to continue reading you must be subscribed

![Atlas Copco_HP BOG[1]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/atlascopco_hpbog1_804720.png)

![Atlas Copco_HP BOG[1]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/atlascopco_hpbog1_804720.png)