Linde advances metal powder innovation with new lab

Industrial gas giant Linde today (21st March) announced that it will launch a new laboratory dedicated to studying and advancing the relationship between atmospheric gases and the manufacture of metal powders.

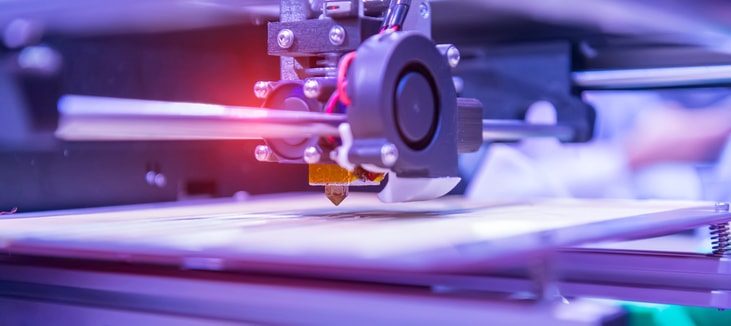

As demand for novel metal powders grow due to the widespread adoption of additive manufacturing (AM) technologies, Linde is attempting to help accelerate the optimisation process through intensive research into gas parameters.

An essential process involved in the manufacture of metal powders is atomisation, traditionally achieved via the operation of large-scale, multi-million-dollar metal powder atomisers.

... to continue reading you must be subscribed