Linde and Evonik alliance advances membrane gas separation processes

The Linde Group and specialty chemicals group Evonik Industries have taken a leap forward in membrane-based gas separation processes after commencing construction on a site expansion in Austria.

The groundbreaking ceremony for the development of Evonik’s membrane production facility was held in Schörfling on 30th September, which will see Evonik’s polymer-based membrane technology being used in gas separation and purification plants of Linde’s Engineering Division.

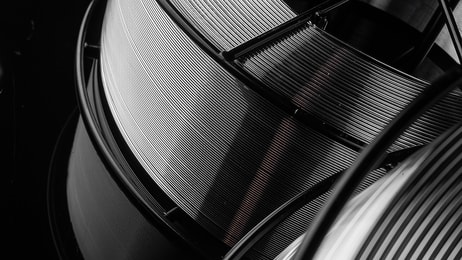

Evonik’s SEPURAN® membranes enable gases such as methane (CH4), nitrogen (N2), hydrogen (H2) and helium (He) to be efficiently isolated in pure form from gas mixtures through more selective separation and higher productivity.

... to continue reading you must be subscribed