Linde Gases enhances welding management service

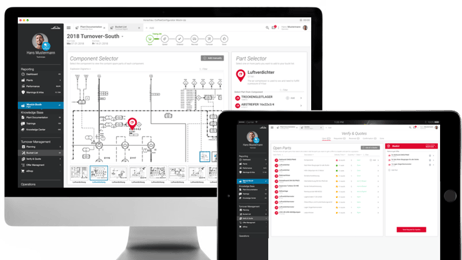

Linde Gases, a division of The Linde Group, has launched the AVANTO™ smart connector, an advanced data capture device to augment the capabilities of its recently introduced welding management solution, AVANTO.

The technology, a state-of-the-art hardware module which connects to the welding machine, will provide a further layer of information to increase traceability, efficiency and quality assurance in welding processes.

The smart connector will capture real-time data about welding operation parameters as they are being performed, such as voltage and current (amps), rate of gas flow, wire speed and arc on/off time. The device is paired wirelessly to a smart phone or tablet and the data collected is transmitted digitally to the cloud-based AVANTO management solution, allowing for real-time comparison of parameters as specified in the welding procedure and the actual process steps being performed by the welder.

“With the addition of smart connector, AVANTO is set to transform the way welding is performed and documented.”

Daren Siddall, Global Marketing Manager at Linde

AVANTO already allows for the capture, monitoring and analysis of a vast amount of data required to manage a modern welding operation – from job and welding procedure creation, management of welder qualifications to the allocation of resources required to complete a weld, such as consumables, shielding gas, welding equipment and welder. The addition of smart connector enables welding supervisory personnel to easily recognise discrepancies between planned and actual process procedures, allowing them to identify and remedy potential problems, such as welder performance and productivity issues.

... to continue reading you must be subscribed