Linde presents LIXSHOOTER bottom injectors for mixer chilling operations

Linde LLC has announced LIXSHOOTER® bottom injectors to help processors of meat, poultry, and other foods, raise the bar on food safety and productivity in mixer chilling operations.

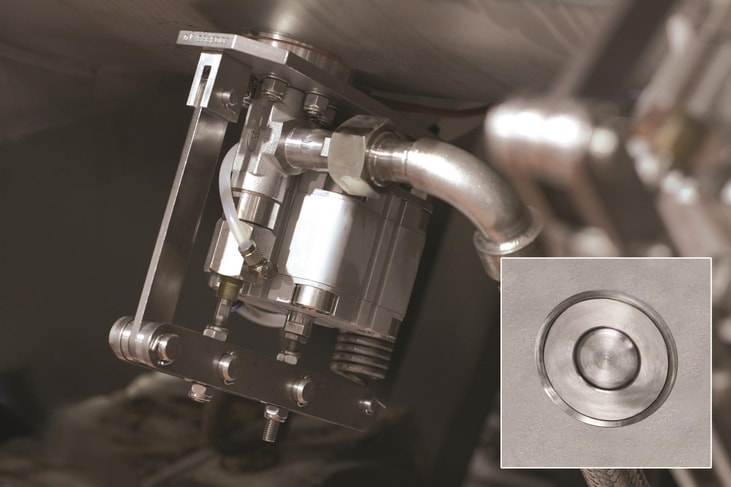

The new injectors are easy to retrofit and feature advanced hygienic design. Unlike other cryogenic bottom-injection (BI) nozzles, the self-sealing injectors are designed to prevent food products from penetrating injector orifices.

The LIXSHOOTER injectors are strategically positioned on the bottom of the mixer, blender or kettle, and can rapidly chill ground meat and poultry mixes.

... to continue reading you must be subscribed