Linde’s cryogenic freezing solutions bring fresh ideas to the par-baked goods market

The Linde Group has unveiled a fresh take on freezing solutions to help preserve the demand for par-baked goods.

The industrial gas giant has developed hygienically-designed cryogenic tunnel freezers and spiral freezers for commercial bakeries in the food and beverage industry.

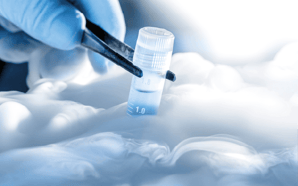

A cryogenic tunnel freezer or a spiral freezer flash freeze food products using controlled blasts of liquid nitrogen (N2) or carbon dioxide (CO2) immediately after baking. The quick freezing action preserves product quality and freshness.

... to continue reading you must be subscribed