LNG18: Exclusive interview with Duncan Gaskin, Marketing Development Manager, Parker Bestobell Valves

The 18th international conference and exhibition on LNG is running throughout this week from 11th-15th April in Perth, Australia. Current and significant impacts on the world’s LNG industry are looming large, with the global event providing a stage for companies within the sector to shine.

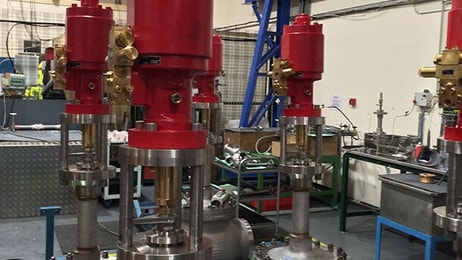

gasworld is bringing you an exclusive interview with a major player in the LNG industry for each day of the conference. Today’s interview is with Duncan Gaskin, Marketing Development Manager at UK-based Parker Bestobell Valves, who explains why the LNG18 event will be a major lifejacket for a sector that’s been under downward pressure for the last 12 months.

Why did Parker Bestobell Valves choose to exhibit at this event? Have you attended before?

... to continue reading you must be subscribed