Marotta Controls expands spacecraft offerings with cryogenic test stand

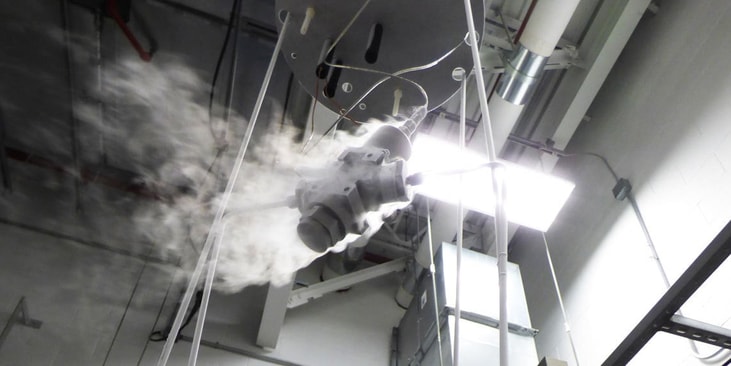

Marotta Controls is now evaluating pressurised components for spacecraft with its new cryogenic test stand, located at the company’s New Jersey facility in the US.

An open top system that uses liquid helium to achieve temperatures lower than -232°C to simulate environmental conditions in space, the stand can be used to collect data for design validation during the development and qualification testing process or as part of environmental stress screening of production units.

The stand installation follows a series of dedicated initiatives driven by Marotta to serve the growing commercial space market. For example, in 2020, the company introduced its first set of CoRe® solenoid valves for cryogenic temperatures designed for commercial launch vehicles.

Already looking at future expansion opportunities, the storage dewar used in the new test stand has a usable volume of 300 cubic inches, making it an optimal container size for large cryogenic components – an important feature as Marotta looks to expand its valve offering to include larger rocket engine components.

... to continue reading you must be subscribed