McPhy presents large-scale electrolysis platforms

McPhy, specialist in equipment for the production, storage and distribution of hydrogen (H2) is presenting its new generation of high-energy efficiency electrolyzers at the Hanover tradeshow.

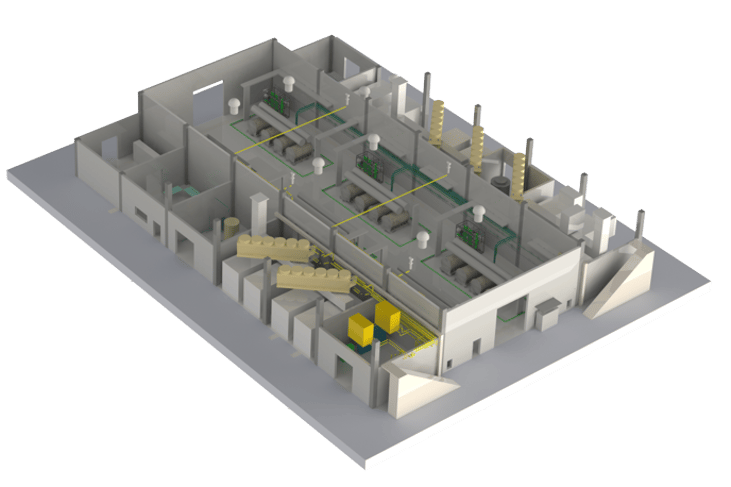

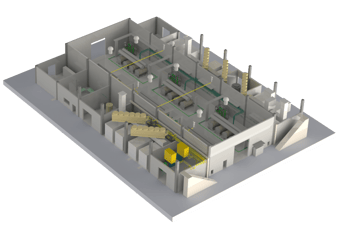

This equipment is integrated into large-scale platforms (4, 20, 100 MW and more), designed to produce low-carbon H2 in the large quantity needed in the industry and heavy transport sectors.

Pascal Mauberger, McPhy’s Chairman and CEO, made the following comments,“McPhy is strongly committed to providing companies in the energy, transport and industry sectors with the leading-edge technology they need to leave fossil fuels behind. We are delighted to announce a major technological advance and the launch of our “Augmented McLyzer” range, that enable us to support our clients as they build up scale: producing H2 on a large scale and at a competitive price, thereby helping to meet the challenge of transitioning to a low-carbon economy. By bringing to market the only alkaline electrolyzers offering this level of performance, McPhy is taking the technological lead in its sector, with an increasingly efficient and competitive product range.”

... to continue reading you must be subscribed