Messer to provide information on gases applications at Formnext Connect

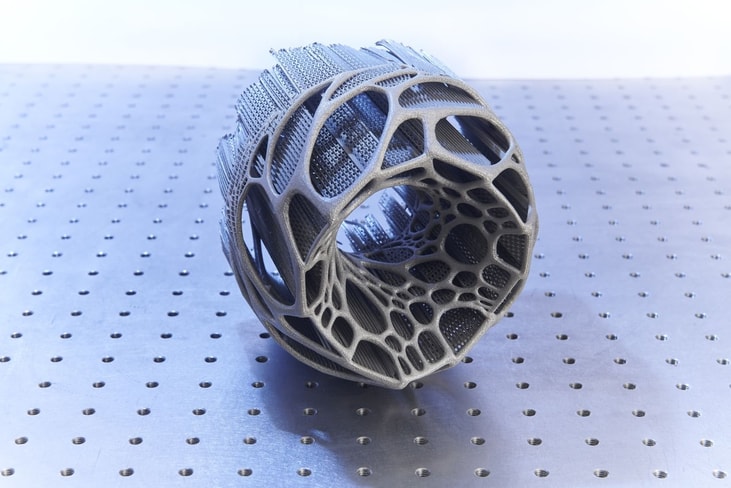

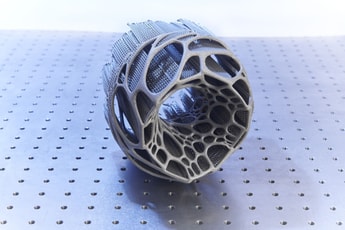

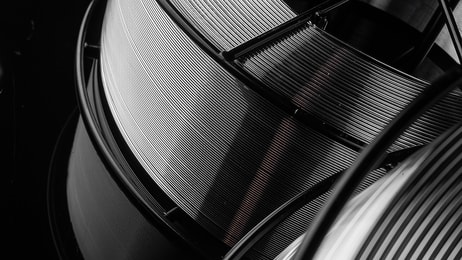

Messer has developed a series of videos demonstrating the gas-assisted process steps of additive manufacturing to showcase at Formnext Connect.

Due to Covid-19, the additive manufacturing trade fair will be held online in 2020 from 10th to 12th November.

Messer will show the videos at the event and its experts will address application-specific questions in the context of virtual meetings.

... to continue reading you must be subscribed