Messer to showcase new material protection product at EUROGUSS 2016

Industrial gases specialist Messer Group will be showcasing a process that uses nitrogen to deburr zinc die-cast products next month, when it attends the EUROGUSS 2016 international trade fair for die casting.

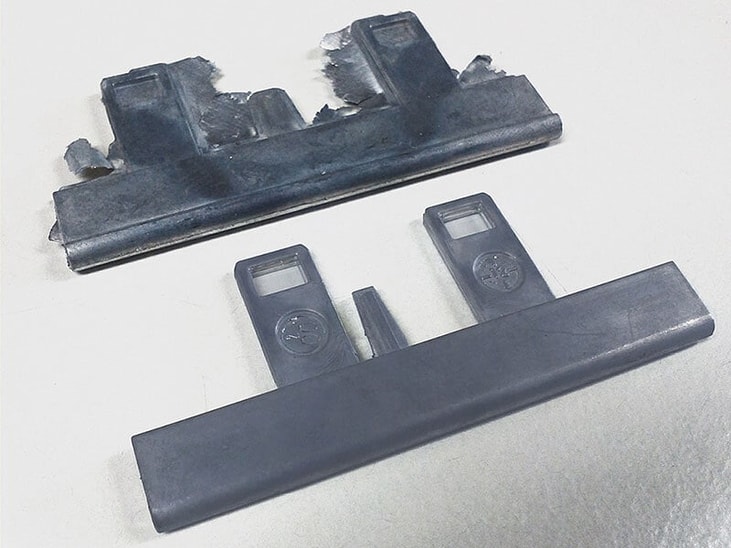

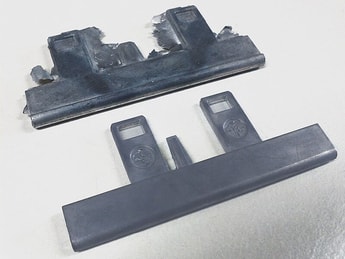

In die casting, it is hardly avoidable to prevent the formation of thin burrs at the seams – burrs which must then be removed after the casting process.

The use of liquid nitrogen and a gentle blasting medium allows this to be done fully automatically and without causing any damage. Deburring zinc, aluminium, titanium and magnesium die castings is thus made easy.

... to continue reading you must be subscribed