Methods 3D improves technology and expands infrastructure

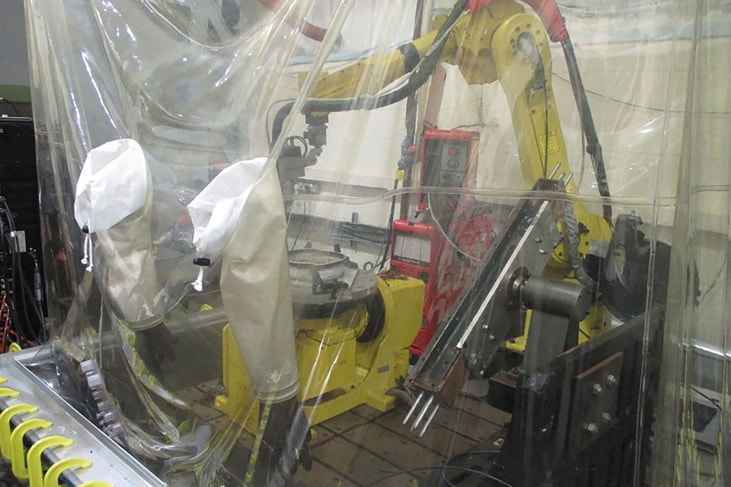

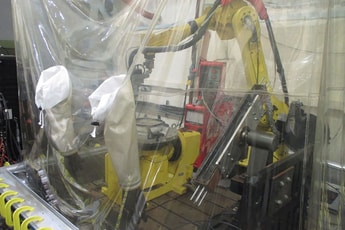

Methods 3D Inc., a newly formed subsidiary of Methods Machine Tools, Inc. continues to broaden its presence in 3D printing through the completion of seven additive manufacturing laboratories located across the U.S.

Methods 3D advanced new additive manufacturing labs are outfitted with 18 printers including Direct Metal Printing (DMP), Select Laser Sintering (SLS), Stereolithography (SLA) and Multi-Jet models running 14 different materials.

Methods 3D has also added personnel to support its new infrastructure, and Mr. James Hanson was appointed as Chief Operating Officer (COO).

... to continue reading you must be subscribed