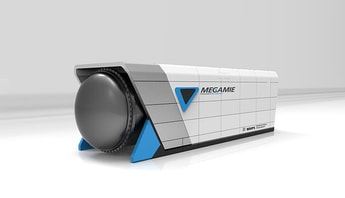

MHPS selects ‘MEGAMIE’ as series name for its integrated fuel cell and gas turbine hybrid power generation system

Mitsubishi Hitachi Power Systems (MHPS) has revealed the name for its pressurised hybrid power generation system that integrates solid oxide fuel cell (SOFC) stacks with micro gas turbines (MGT).

‘MEGAMIE’, developed for the commercial and industrial market, is a combination of ‘mega’ – evoking an image of the high-output fuel cells with stable operating performance – and ‘megami’ – a Japanese word meaning goddess of the land or beauty.

“The blended term conveys strength, elegance, and warmth,” MHPS explained. “The final ‘E’ represents the three ‘Es’ of Environment (environmental conservation), Energy security (stable supply), and Economy (economic efficiency), thereby expressing the value that MHPS provides to customers, and the role the company plays in society.”

... to continue reading you must be subscribed