Mitsubishi consortium to recycle CO2 for methanol production

Mitsubishi Power Systems (MHPS), Mitsubishi Heavy Industries Engineering (MHIENG) and Mitsubishi Gas Chemical Company (MGC) have joined forces to conduct research on the recycling carbon dioxide.

The companies were selected by the New Energy and Industrial Technology Development Organisation to carry out the research from a refinery at Tomakomai City, Hokkaido Japan, where CO2 is captured and stored by an existing demonstration plant.

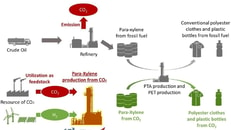

Together, the companies will collaborate on research activities for carbon capture and utilisation (CCU) in order to produce methanol from captured CO2.

Leader of the consortium MHPS, proposed using captured CO2 to synthesize methanol, which is a key fuel and raw material in a wide range of industries.

... to continue reading you must be subscribed