“Moment of pride” for INOXCVA

Various laboratories around the world have successfully demonstrated the initiation of fusion reaction, which is when two hydrogen isotopes fuse together to form helium and produce heat during this nuclear reaction.

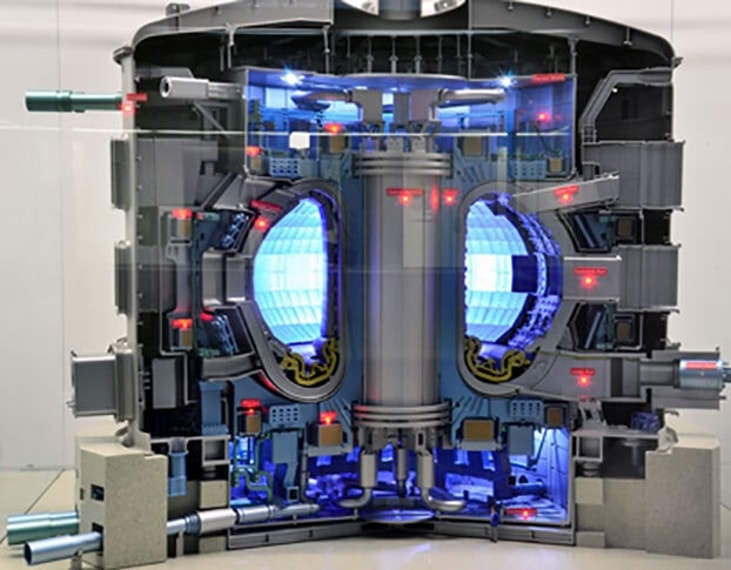

To prove the viability of such energy generation on an industrial scale, a global cooperation was initiated. The Agency leading this global initiative, ITER, will be the world’s largest experimental facility to demonstrate the scientific and technical feasibility of fusion power.

The project, name ITER which also means “the way” in Latin, is being constructed presently at St. Paul-lez Durance, in the South of France. The construction cost of ITER is estimated at €13bn over ten years. A unique feature of this project is that it is being realised through in kind contribution from seven partners, namely; China, the EU, India, Japan, Korea, Russia and USA.

The cryogenic technology will be extensively used for the ITER project to create and maintain low-temperature conditions near absolute zero for the superconducting magnets, cryo-pumps to create vacuum and some diagnostics systems. Long and complex cryogenic transfer lines will be required for transporting the cold power from the source to the superconducting magnets as well as to other systems.

... to continue reading you must be subscribed