New process for semiconductor wafer cleaning

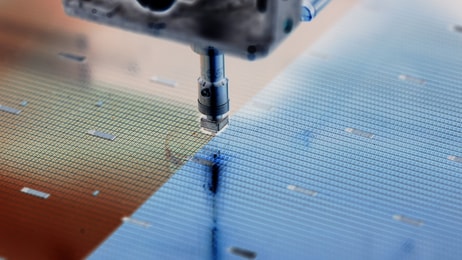

A new process has been introduced for semiconductor wafer cleaning, eliminating the negative side effects of traditional plasma cleaning.

The process has been introduced by Eco-Snow Systems, a member of the BOC Group and a leading supplier of dry carbon dioxide snow-based wafer cleaning tools.

Unlike traditional oxygen plasma cleaning, the new CO2-based dry process will not promote oxide layer growth, silicon loss or mobile ion diffusion which can negatively affect device performance. The new process can also be combined with conventional wet cleaning to achieve the required surface conditioning of the semiconductor wafer surface.

The process is conducted in a new cleaning tool, WaferClean 36000, which can process both 200 and 300mm wafers.

... to continue reading you must be subscribed