Air Products receives laser industry awards

Air Products has recently won the 2014 Ringier Technology Innovation Awards for the Laser Industry in China, for its specialist BIP® purification technology.

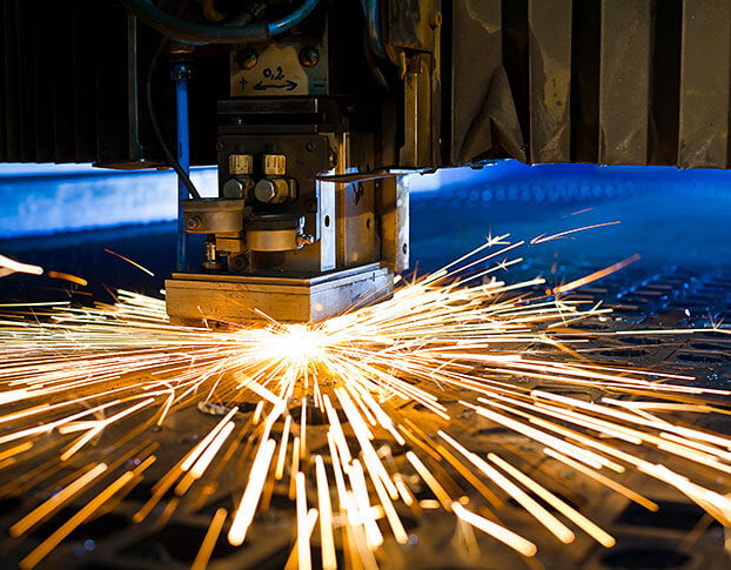

The technology is recognised for its innovation and reliability on gas purification, which results in production efficiency and cost effectiveness in gas analysis, high quality welding and laser cutting.

BIP® is named from one of its most important features: the specially designed ‘Built-In Purifier’. The product is used to produce ultra high purity gas range for a wide variety of applications requiring high purity gases, including laser cutting, high quality welding, gas chromatography, and inerting.

... to continue reading you must be subscribed