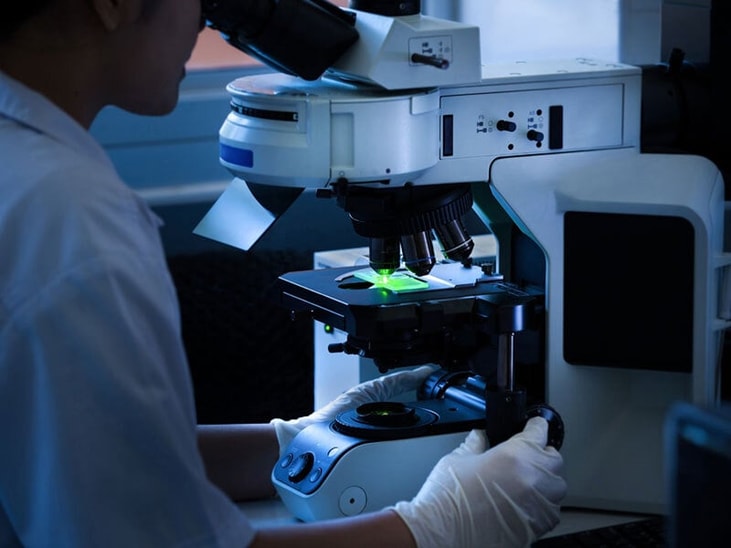

Oerlikon Leybold Vacuum creates smart high vacuum system for researchers

Oerlikon Leybold Vacuum, a leading global technology group from Switzerland, has created a new, smart high vacuum system for researchers.

The TURBOLAB generation is a plug-and-play high vacuum system with an enhanced pump performance and boasts a new compact mobile design.

The new TURBOVAC i/iX turbo pumps feature a unique, oil-free hybrid bearing design, so when used with dry compressing backing pumps it generates a hydrocarbon free pump system.

... to continue reading you must be subscribed