On-site Oxygen Generation – The Advantages of VSA

PCI (www.pcigases.com), a Californiabased on-site industrial gas manufacturer, was founded in 1984 to manufacture cryogenic air separation devices for operation in extreme and remote environments. Since then, PCI has continually expanded its technology platforms to include nitrogen membrane systems and Vacuum Swing Adsorption (VSA) oxygen systems.

This article presents PCI’s VSA oxygen technology and compares it to other forms of oxygen supply in its size class.

Oxygen Technology Comparison

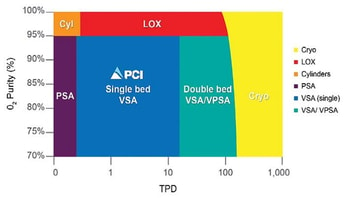

Within the oxygen requirements of 0.3 to 40 short tons/day (tpd), or 200 K to 25 MM cf/mo in merchant LOX terms, and oxygen purities less than 95 percent, the traditional form of onsite oxygen generation has been the Pressure Swing Adsorption (PSA) system below 20 tpd and double-bed Vacuum Pressure Swing Adsorption (VPSA) systems above 20 tpd. PSA and VPSA systems require a complicated set of valves and twice as much power as VSA systems. Therefore, their total cost of ownership is typically equivalent to or higher than liquid oxygen (LOX) deliveries. Hence, many customers who are presented with the option of PSA systems or LOX supply will choose the latter for reliability purposes. PCI’s Deployable Oxygen Concentrator Systems (DOCS) are designed with a much simpler approach to on-site oxygen supply as they conserve half the power used by PSA systems and significantly reduce maintenance costs. Compared to traditional double-bed VSAs, the single- bed DOCS VSAs reduce capital costs and complexity at a slight trade-off in power efficiency. For customers with requirements typically supplied by LOX, PSAs, or double-bed VSAs between 0.3 and 40 tpd, a DOCS VSA on-site plant in many instances can offer the lowest equivalent cost of oxygen.

While LOX supply costs for a typical customer consuming greater than 2 MM cf/mo may range from $0.30/ccf up to $0.85/ccf depending on distance from an air separation plant (ASU), a VSA on-site plant can be competitive even with LOX users in close proximity. For instance, a customer located close to an ASU with a requirement for 2 MM cf/mo may pay $0.40/ccf and a tank rental charge of $1200/mo. A 10-year discounted cash flow (DCF) model indicates that a customer will typically achieve less than a threeyear payback with a VSA on-site plant. This model assumed a discount rate of 12 percent, standard escalations for energy prices, maintenance costs, and LOX, as well as a 95 percent utilization of the VSA.

... to continue reading you must be subscribed