Optimise refinery operations with RTS Africa’s hydrogen analyser

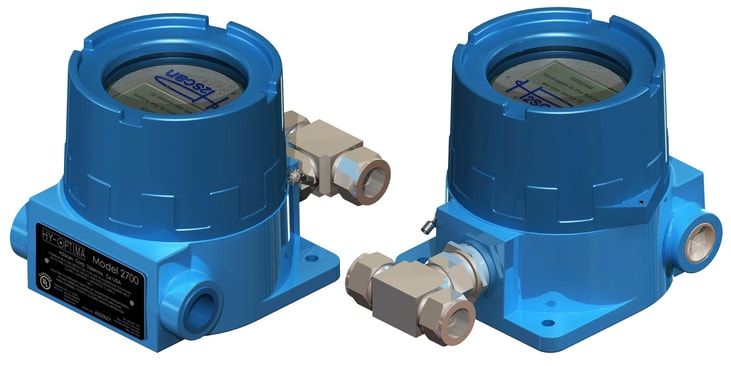

RTS Africa’s Hy-Optima 2700 hydrogen (H2) analysers for accurate monitoring and optimised performance in oil refining.

RTS Africa’s Hy-Optima’s 2700 hydrogen (H2) analyser with solid-state, non-consumable sensor provides real-time continuous H2 concentration data so that process engineers know the exact percentages of H2 throughout the refining procedure.

With real-time H2 monitoring, process engineers have an overview of exactly what is taking place in any complex refinery process stream. This means early detection of any problems and, ultimately, the refinery is able to produce better products more economically. Improved energy efficiencies result in reduced maintenance and downtime costs.

... to continue reading you must be subscribed