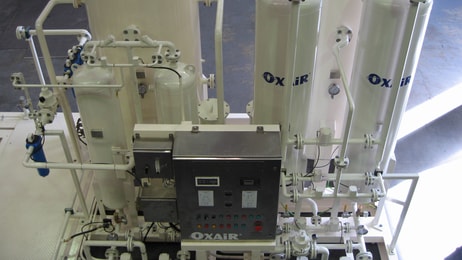

Oxair releases nitrogen membrane generator

Oxair’s nitrogen membrane systems supply a range of volume requirements up to 5,000 M3/hr (170,000 SCFH with a range of purities up to 99.9%), delivering a constant flow of high purity nitrogen gas.

The Australian-based company has released its new PRISM® membrane system, which suits larger nitrogen demands, especially in remote locations such as oil platforms and chemical plants.

The technology can be used directly by the end user on demand, eliminating the need for cylinders, dewars or tanks.

“Companies have different demands but need to adapt to a dynamic marketplace and squeeze every cent out of production processes. Ensuring a constant supply of nitrogen is a crucial requirement for many industry sectors. Nitrogen membrane generators can safeguard supplies and help operators become self-sufficient in this important gas,” said James Newell, CEO of Oxair.

... to continue reading you must be subscribed