Poultry processors turn to cryogenic mixer-chilling

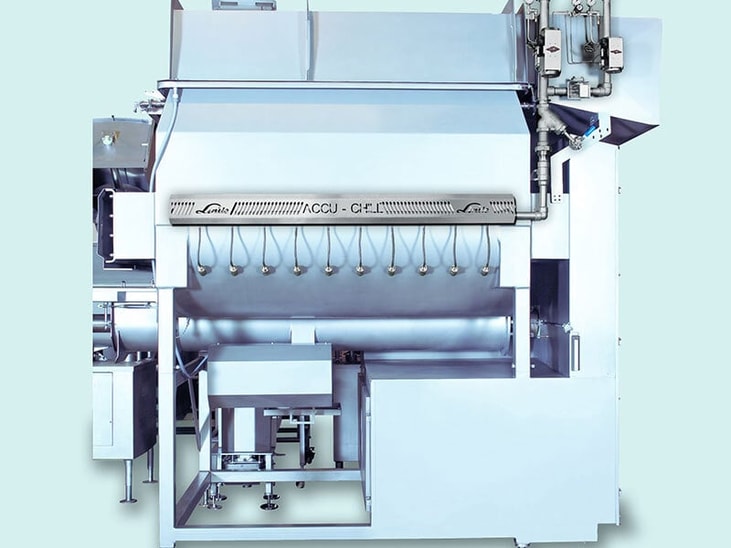

A chilling system from Linde, which can use either liquid carbon dioxide or liquid nitrogen, could be the system of choice for the booming poultry industry – which continues to see production increase.

With the US consuming more chicken than ever, expected to rise more than 2% in 2015, poultry processors are eager to improve efficiencies. Ready-to-cook poultry production topped more than 4.15 billion lbs (1.88 billion kg) in October – and much is processed into formed product.

“Small improvements in processing efficiencies for formed poultry can mean millions of dollars on the bottom line across an entire operation,” says Mark DiMaggio, Head of Food & Beverage, Linde LLC.

Cryogenic bottom-injection (BI) chilling systems – precisely engineered to poultry mixers – can help ensure consistent product quality, repeatable mixing and forming operations, and increase line production. “Even mixer-chilling systems installed just a few years ago can potentially benefit from the latest technology and custom engineering,” he said.

... to continue reading you must be subscribed