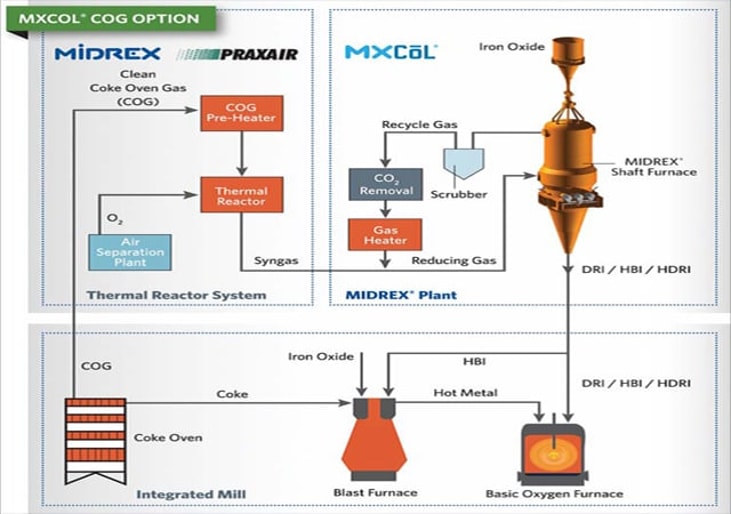

Praxair and Midrex Commercialize Technology to Produce DRI Using Alternative Fuels

Praxair, Inc. (praxair.com) and Midrex Technologies Inc. (midrex.com) have signed a strategic alliance agreement to develop and market new process technology for the production of direct reduced iron (DRI) with a variety of fuels such as coke oven gas. The new process uses an innovative partial oxidation technology to convert hydrocarbon fuels into high quality, high temperature syngas suitable for DRI production.

DRI Production

DRI is a valuable scrap-substitute material that is used as feedstock in steelmaking, typically in electric arc furnaces. Midrex, based in Charlotte, NC, and a wholly owned subsidiary of Kobe Steel, is the global market leader in shaft furnace DRI technology. Their process uses iron ore and natural gas to produce DRI in a shaft furnace. Natural gas (methane) is first reformed to produce hydrogen (H2) and carbon monoxide (CO) in an approximately 2:1 ratio, and then these gases are reacted with the iron ore pellets at 800–1,000°C to produce the metallic DRI.

While the global production of DRI has continued to rise to a record high 73 million tons in 2011, it is concentrated in just a few geographic regions such as the Middle East, Venezuela, India, and Mexico, where natural gas, the primary fuel source for DRI production, is relatively cheap. However, DRI production has not been an economical option in a majority of the world’s largest steelmaking regions due to high natural gas cost or limited availability; in fact, seven of the 10 largest steel producing countries produced no DRI at all.

While the global production of DRI has continued to rise to a record high 73 million tons in 2011, it is concentrated in just a few geographic regions such as the Middle East, Venezuela, India, and Mexico, where natural gas, the primary fuel source for DRI production, is relatively cheap.

Under the new alliance, Praxair and Midrex will develop and market a new Thermal Reactor System that will allow DRI production using a variety of alternate fuels such as coke oven gas (COG), thus opening up and broadening the market for DRI. This DRI can be charged into an electric arc furnace, blast furnace, and/or a BOF (Basic Oxygen Furnace) converter. “With the help of Praxair’s unique technology we can open up new markets and offer more attractive choices for the production of DRI, especially in regions where traditional DRI fuels such as natural gas are not economically available,” said Stephen Montague, Vice President of Sales and Marketing for Midrex Technologies, Inc.

... to continue reading you must be subscribed