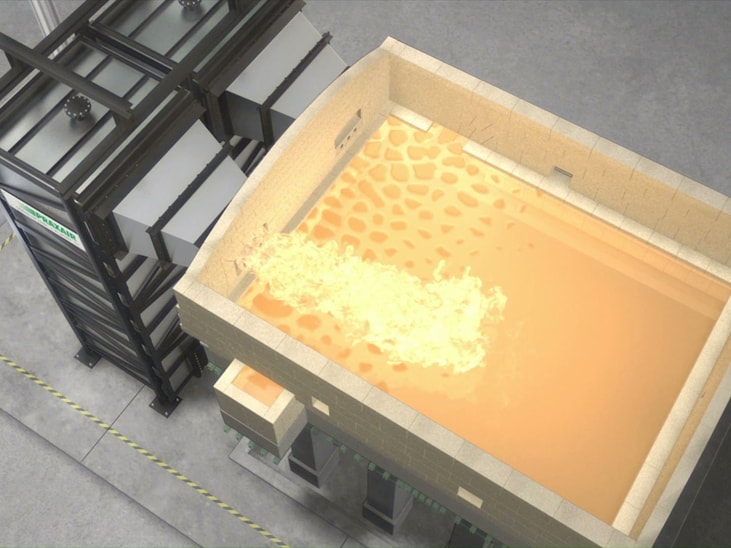

Praxair’s thermochemical regenerator system provides productivity gains

Praxair, Inc. has signed a contract with Libbey, one of the largest glassware and tableware manufacturers globally, to supply it with Praxair’s OPTIMELT thermochemical regenerator (TCR) system.

The company has also entered into a longterm contract with Libbey to deliver oxygen (O2) to its glass melting facility in the Netherlands through a non-cryogenic, vacuum pressure swing adsorption (VPSA) system.

Both the OPTIMELT TCR system and the 60 tonnes per day (tpd) VPSA O2 onsite supply system are scheduled to start up in 2017.

... to continue reading you must be subscribed

![AirSep IMG_2505[4]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/airsepimg_25054_441494.jpg)

![AirSep IMG_2505[4]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/airsepimg_25054_441494.jpg)