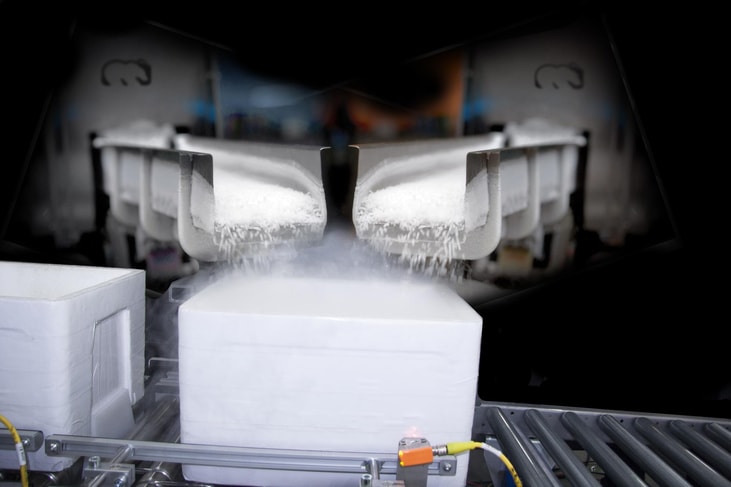

Putting the vaccine on ice

Gene Cooke admits it was ‘truly fortuitous’ that Cold Jet completed an expansion of its main manufacturing facility just before the coronavirus (Covid-19) outbreak, which has helped the Loveland, Ohio-based company keep pace with a fivefold increase in its machines that make dry ice.

“It went from 0mph to 60mph overnight,” the Cold Jet President and CEO told gasworld.

Cold Jet’s products are being used by Covid-19 vaccine manufacturer Pfizer-BioNTech as well as by distribution companies, which need the dry ice for storage and transportation of the vaccines. Driven by the development of vaccines through the summer, and then the authorization of the Pfizer-BioNTech vaccine in December, Cold Jet has never known demand like it.

... to continue reading you must be subscribed