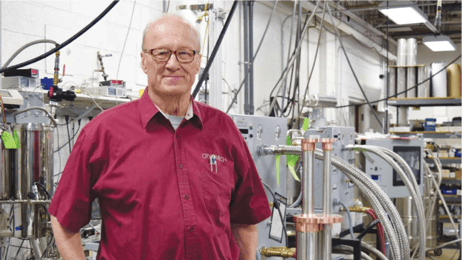

Q&A: An insight into Ranch Cryogenics

Air separation specialist Ranch Cryogenics Inc. (RCI), will be celebrating its 30th anniversary in August.

The family business was created in 1987 by current CEO Mike Duffy Sr., it found its voice during the economic boom of the 1990s, and came of age in the 21st century as the demand for liquid oxygen (O2), hydrogen (H2) and other gasses soared to accommodate new manufacturing markets.

RCI enters its fourth decade in a new home outside of Chicago. The son of Mike Duffy Sr., Mike Duffy Jr., is the current President, and Michael “Trey” Duffy, the youngest member of the Duffy family, is Vice-President and General Manager.

... to continue reading you must be subscribed