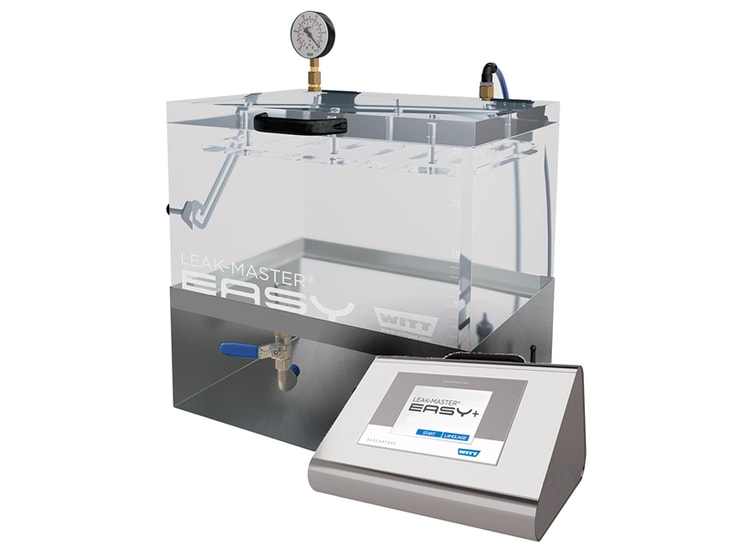

Witt’s Leak-Master has undergone a redevelopment and now benefits from electronic control

Witt’s new Leak-Master excels at finding even the smallest holes in rigid or flexible packaging quickly and precisely.

Information about Witt’s device, states that inert gas and vacuum packaging can be tested for leaks, it’s easy and it doesn’t involve trace gas. The test product is placed in a chamber filled with water. When the lid is closed, the air space above the water level is evacuated, the package inflating under water. If air bubbles emerge, there is a leak. This test method is especially straightforward and cost effective and has the additional advantage that the weak point of the packaging is visible.

Sparing the trees

But the newer Witt Plus version of the Leak-Master Easy can do even more – as it records, saves and communicates (via Ethernet and SD card) its test programme and results. This does away with tiresome and time-consuming logging by hand -meaning QC/QA Managers can check all leak test results at any time, especially those increasingly associated with Certification and Customer KPIs.

... to continue reading you must be subscribed