Reliquefaction market entry for Bestobell

Bestobell Marine has secured two new high profile contracts for its cryogenic globe and check valves to be installed for use in LNG reliquefaction – which is a company first.

The valves are to be fitted on two LNG carriers being built at HHI (Hyundai Heavy Industries) shipyard in South Korea for Knutsen OAS Shipping of Norway. Similar systems will also be installed on two sister ships being built by Imabari Shipbuilding Group in Japan for Elcano.

This is the first time that Bestobell Marine has supplied its globe and check valves for LNG re-liquefaction applications. The company has previously supplied cryogenic globe and check valves for re-gasification systems, including for the five Hoegh FSRUs (Floating Storage Regasification Units) that have been constructed at the HHI shipyard.

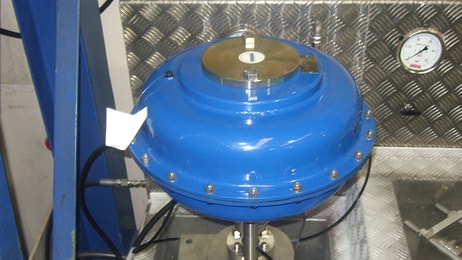

Bestobell Marine’s cryogenic globe valves are fully fire-safe and leak-free, based on a proven design that has been used by the company for over a decade for LNG ship applications.

... to continue reading you must be subscribed