Robotic Welding at Weldcoa

The founder of Weldcoa, Richard Bennett, invented the Sur-Loc™ Pallet in the late 1960s. Since that time the Weldcoa Palletized Process has evolved from an external delivery system, through the use of pallet trucks and trailers, to an internal material handling system that can include two-tiered storage and manual or automated gas-filling systems. Today, it is the most widely used pallet system in North America.

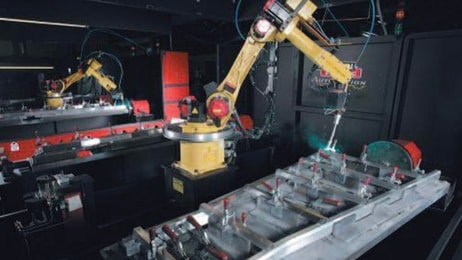

Weldcoa’s 355 East Sullivan Road facility in Aurora, Illinois is dedicated to its steel fabrication, assembly, manifolds, and lead production. It is here that the Sur-Loc pallets are built. Jim Cook, Weldcoa’s Inside Sales Manager, says, “Our Sur-Loc pallets are the strongest in the industry. They’re manufactured right here in Illinois using robotic welders to ensure precision.” Like the pallet system itself, the processes used to manufacture these pallets and palletized systems have evolved. Cook, who has been with Weldcoa for over nine years, including as an operations manager, explains how the robotic welder has transformed their pallet manufacturing operation.

“Weldcoa’s former hand welding production process for pallets required five to six employees to produce about 10 to12 pallets a day. When the first robot, an IGM dual station robot, was installed, only one person was needed to oversee the production of 40 to 50 pallets a day. This represented a huge gain in productivity.”

In 2004/2005, Weldcoa installed a custom Panasonic dual arm welder using 350 dip pulse. Panasonic supplies the technical training and support for this robot, which uses a 90/10 mixture of carbon dioxide and argon. Cook says, “The robotic welder can weld anything that the hand held welders do. Today all structural weld joints are done robotically. The only piece that is still done by hand on a fixture is the pallet lock assembly. This is a sub-assembly of the pallet that is inserted into the robotic fixture when completed and all the other steel components have been added to the fixture. From that point, the robot takes over.”

... to continue reading you must be subscribed