Safety, productivity and renewability: Why MagneGas believes its alternative fuel is the way forward

Tampa, Florida-based MagneGas® Corporation has entered into its largest equipment sale to date, with a Letter of Intent (LOI) to manufacture and deliver equipment and supplies to an as-yet-unnamed company based in Germany.

With it, the innovative alternative energy company has the opportunity to open up more new markets for its proprietary gasification and sterilisation systems and pioneering MagneGas2® fuel.

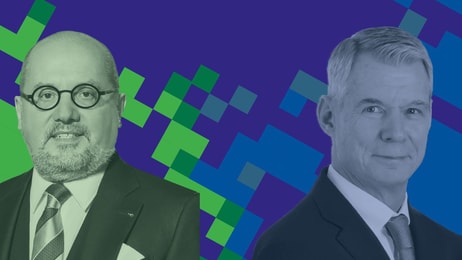

Asked if this was a real breakthrough for the company, CEO Ermanno Santilli exclusively told gasworld, “It is very significant for the company as it represents three critical milestones. First, it is the largest equipment sale in the history of the company. That says much on its own.”

... to continue reading you must be subscribed