Sandia National Laboratories promoting safety of liquid hydrogen fuel stations

Sandia National Laboratories, operated by National Technology and Engineering Solutions of Sandia LLC, a wholly owned subsidiary of Honeywell International Inc., for the U.S. Department of Energy’s National Nuclear Security Administration, is working to design the next generation of hydrogen (H2) stations.

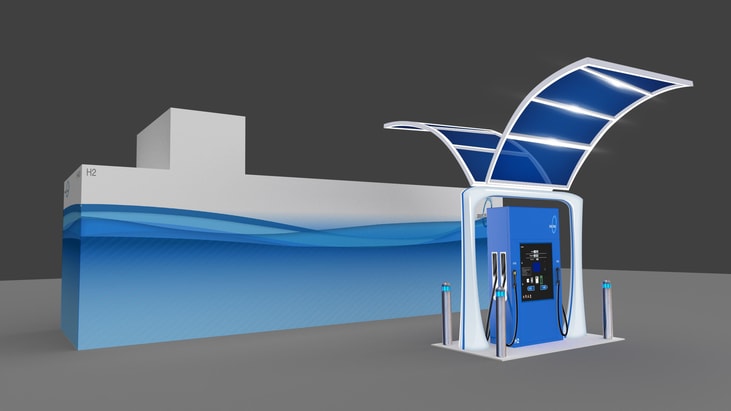

Sandia helped design the first generation of fuelling stations for H2-powered cars so that they’re as safe as conventional gas stations. Now, to keep up with growing demand for H2 fuel Sandia is working to switch the fuelling stations from gaseous to liquid H2. Liquid H2 is denser than gas, enabling retailers to store more of it in the same amount of space.

A new Cooperative Research and Development Agreement with Sandia will allow the largest H2 retailer in the US to date, First Element Fuel, to build many more of these cutting-edge liquid H2 stations. It will also help modernise the National Fire Protection Association safety codes pertaining to liquid H2 safety distances, which have not been updated in decades. The updated codes will in turn benefit H2 retailers and fire marshals in designing and permitting new, safer stations.

... to continue reading you must be subscribed

![Renewable energy[3]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/renewableenergy3_624162.jpg)

![Renewable energy[3]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/renewableenergy3_624162.jpg)