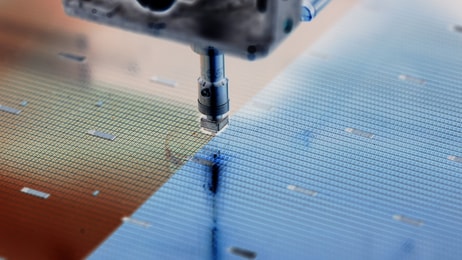

SEMICON Singapore 2009 to showcase semiconductor trends

More than 120 companies from around the world are to gather in South East Asia later this month, as SEMI Singapore Pte Ltd hosts the SEMICON Singapore 2009 Exposition from 20th – 22nd May.

To be held at the Suntec Singapore International Convention and Exhibition Centre, SEMICON Singapore has been held annually since 1993 and is Southeast Asia’s premier microelectronics exposition dedicated to semiconductor manufacturing technology.

The event provides a neutral platform for industry players to converge and exchange technical ideas and develop business opportunities.

According to a statement issued by SEMI Singapore, more than 120 companies from around the globe will exhibit their latest products and technologies in semiconductor and photovoltaic (PV) manufacturing – both ever-increasing consumers of industrial and specialty gases.

... to continue reading you must be subscribed