Shrinking to fit using cryogenics – Cryotherm analyses the market

Cooling baths, filled with LiN, has been used to obtain a quick and reliable method of establishing a fit between automotive and engineering components – such as piston pin, connecting rod bushings and valve seat rings.

The latest application to join this trend is the production of integrated valve train modules – using a technique jointly developed by Volkswagen Sachsen, the Chemnitz-based development centre IAV and the special-purpose machine manufacturer USK in Limbach-Oberfrohna.

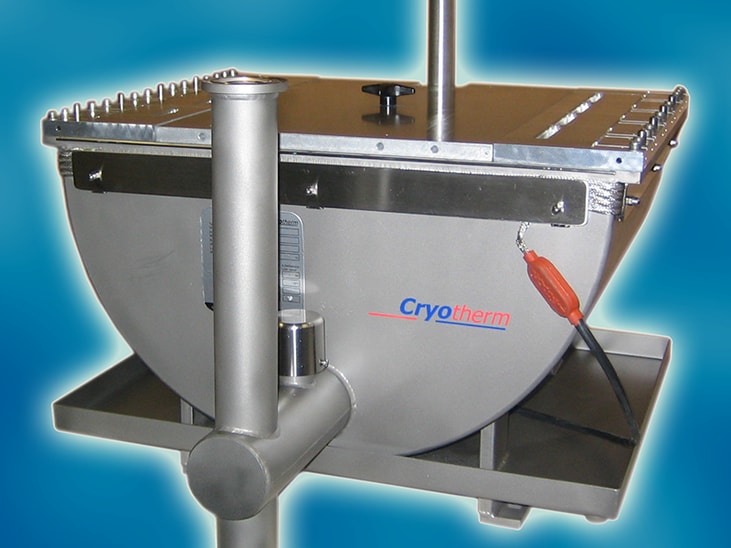

For this new joining technique, industrial gases specialist Cryotherm provides customised cooling baths and auxiliary equipment for a reliable supply of liquid nitrogen.

Cold makes it fit

... to continue reading you must be subscribed