Air Products unit to supply nitrogen for chips and build novel ASU

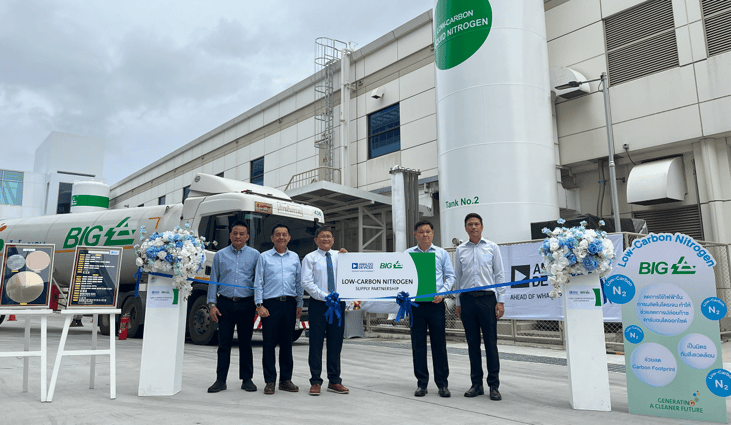

Thailand-based Air Products subsidiary BIG has picked up new business in air gases.

It is to supply low-carbon nitrogen to Analog Devices (Thailand) Co, a global semiconductor manufacturer, for use in its production and product testing processes.

The supply contract is notable for Thailand’s electronics and semiconductor industry in being the first to integrate low-carbon nitrogen directly into the manufacturing process.

... to continue reading you must be subscribed