C-Capture launches trial to capture carbon from cement sector

UK-based C-Capture has started up a new trial at a cement-making plant in Lincolnshire which aims to test the company’s technology to remove carbon dioxide (CO2) from the flue gas emissions produced during cement manufacture.

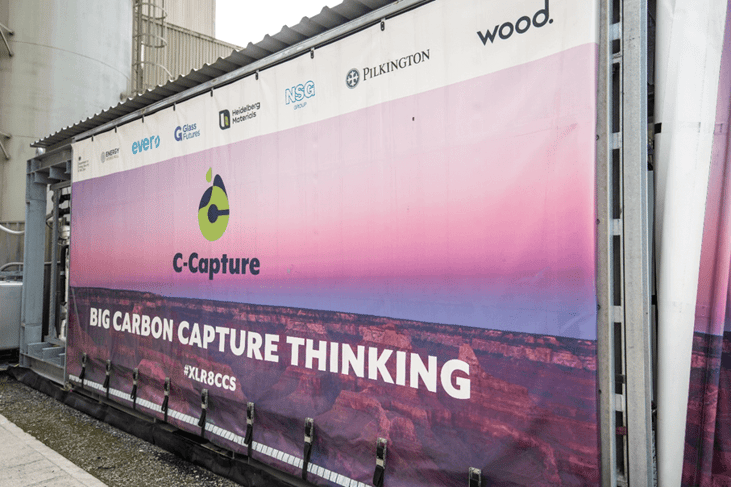

As part of the ongoing XLR8 CCS project, a new carbon capture solvent compatibility unit (CCSCU) designed and built by C-Capture and partner Wood is now installed and operating at the Heidelberg Materials cement plant.

The project will explore the potential for C-Capture’s technology to reduce emissions across three hard-to-abate industries: energy from waste, cement and glass manufacturing.

... to continue reading you must be subscribed