De-risking green hydrogen and ammonia projects

Stephen B. Harrison from sbh4 consulting outlines how to protect electrolyser investments with ultrapure water

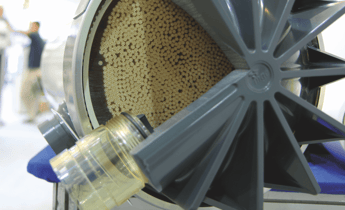

The dominant path to green hydrogen is splitting ultrapure water using renewable electrical power on an electrolyser. For each kg of green hydrogen produced, 9 to 10 litres of water are consumed by electrolysis.

This equates to circa 200 litres of water per MW of electrolyser capacity. To generate that amount of ultrapure water, circa 1.5 times as much fresh water is required. And to generate desalinated fresh water, approximately twice as much seawater is required. So, for each litre of ultrapure water, 3 litres of seawater must be processed.

There are many steps between seawater and ultrapure water. If any of those fails, the electrolyser stack could be damaged beyond repair. If the water processing plant fails, the electrolyser must shut down, resulting in failure to supply off takers, or causing problems with downstream ammonia synthesis. Reliability and consistent ultrapure water quality are key.

... to continue reading you must be subscribed