EU-funded pilot project claims hydrogen liquefaction breakthrough

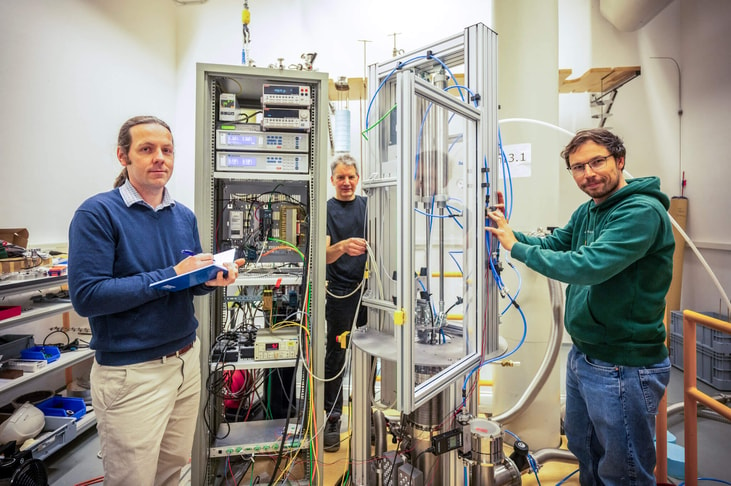

An EU-funded project has launched the continent’s first magnetocaloric pilot plant which could reduce hydrogen liquefaction costs to below €1.50 per kilo.

The pilot, developed with HyLical by Helmholtz-Zentrum Dresden-Rossendorf (HZDR) and startup Magnotherm, may pave the way for large-scale industrial applications.

Magnetic cooling technology represents a new type of climate-friendly and energy-efficient power, without compressors and environmentally harmful refrigerant gases.

The magnetocaloric effect occurs when materials with certain properties – such as lanthanum-iron-silicon alloy (LaFeSi) – are placed in a magnetic field.

Depending on the orientation of the magnetic moments, the metallic materials can cause a sudden drop or rise in temperature. Using this principle, it is possible to cool hydrogen to –253°C after pre-cooling with liquid nitrogen. This triggers liquefaction.

Dr Tino Gottschall, scientist at HZDR’s High Magnetic Field Laboratory Dresden (HLD), has long envisiged a plant capable of producing 5,000kg of liquid hydrogen per day that is significantly more efficient and affordable than today’s liquefaction methods.

The next target is to increase efficiency to produce 100kg of liquid hydrogen per day, to demonstrate the scalability of the technology for industrial deployment.