Force Technology gears up for MEGA loop launch

The MEGA loop will be the largest closed loop for custody transfer calibration of flow meters when it goes into operation this year, according to Force Technology, and the €10m investment is the largest in the company’s 80-year history.

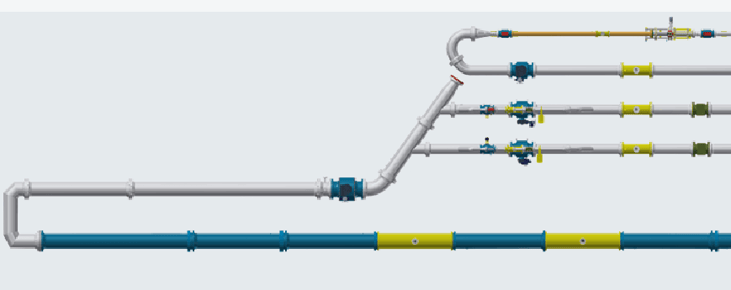

The MEGA loop has been ‘revitalised’ in regards to technical capabilities and future-proofed towards the changing energy mix, in order to be hydrogen ready (initially up to 25%), as well as split into two independent calibration strings. It will be ‘larger than first intended’ in the initial phase. The (Re)calibration workshop and launch is scheduled for May 10-12 in Denmark.

The technology is similar to that used in previous facilities built in 2003, 2010 and 2012; the only difference is this one is three times bigger, due to customer demand. Manufacturers of the big flow meters haven’t had a facility where gases can be calibrated – they’ve just had to trust supplier readings from the factories – so it presents a new customer offering.

It will be able to calibrate flow meters in all sizes with a pressure of 0-65 bar, flow of 0-50,000 m3/h, and calibration accuracy of less than 0.15%.

... to continue reading you must be subscribed