HydroGraph signs gas supply deal and plans Texas graphene plant

US-based HydroGraph Clean Power, a sustainable manufacturer of pristine graphene, has partnered with a North American industrial gas supplier and is advancing plans for a new production facility in Texas, outlined in an April letter of intent.

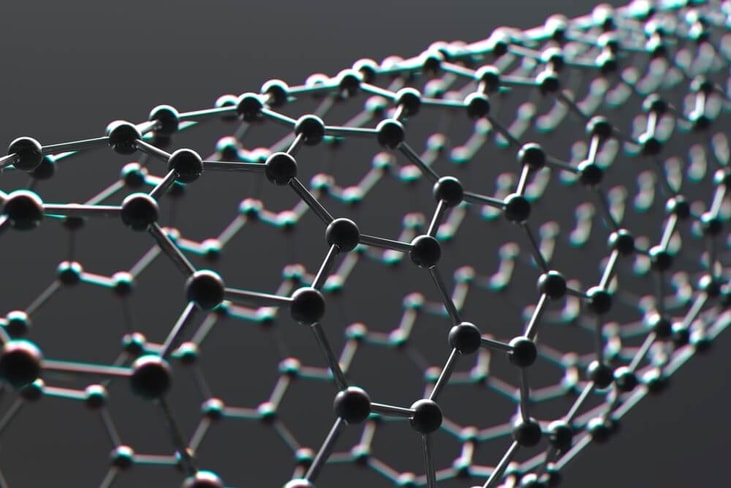

The agreement ensures a continuous supply of high-purity acetylene, a crucial feedstock for HydroGraph’s detonation synthesis process, which produces high-quality graphene. This process uses controlled explosions to create high-pressure, high-temperature conditions followed by rapid cooling.

Acetylene is a highly reactive and unstable fuel that undergoes detonation when mixed with oxygen or other oxidisers and can even detonate in an oxygen-free environment.

After detonation, the tiny carbon-rich molecules rapidly polymerise. This is when many small molecules stick together to make a bigger molecule. In this case, these carbon atoms self-organise to form a two dimensional graphene structure.

... to continue reading you must be subscribed