As growth in the search for green-energy solutions continues globally, the importance of and demand for cryogenic feedstocks – liquid hydrogen, nitrogen, oxygen and carbon dioxide – continues apace.

However, the use of these next-generation fuels and energy sources depends on safe, reliable and efficient ways of manufacturing them – and converting them from liquid to gas, when necessary.

Selection of the correct vaporiser is critical to the proper function of any cryogenic-vaporisation system.

In a new white paper, OPW Clean Energy Solutions, through its ACME Cryogenics and CEXI product brands, explains how it offers the industry a complete line of vaporiser types and ancillary components, all of which have been designed, tested, developed and proven to deliver the highest level of performance in critical cryogenic-vaporisation processes.

Location, energy sources, vaporiser size, and operation times are key determining factors.

Generally, the design of the system will see the vaporiser positioned near the cryogenic liquid’s storage tank, but there is no single, best-practice approach, so the final design ultimately will be based on the needs of the individual application. Considering where the system will be used will help determine the type of heat source that is best to be used to vaporise the fluid.

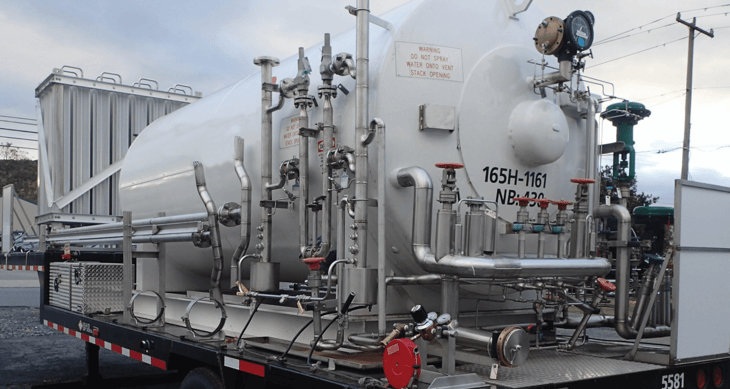

Typically, the end-user customer will collaborate with the vaporiser manufacturer and supplier to help design the best system. For example, in some cases the system might require placing the vaporiser on a skid so that it can be relocated within the manufacturing facility or plant as needed.

The final system also may require more than one vaporiser size or type – for example, if a manufacturer works with different kinds of cryogenic liquids in its processes.

Facilities that work with hydrogen, nitrogen, CO2, and oxygen will need a different type of vaporiser for each liquid because each of these liquids has a different temperature set-point at which it converts from liquid to gas.

And if the system requires electricity you need to factor in if the grid will provide enough voltage to keep the system operational, especially if it needs to work around-the-clock.

Crucially, it is important to choose a vaporiser type with a design and operation that can satisfy all the safety protocols associated with the vaporisation of cryogenic liquids.

In the realm of vaporiser design and manufacture, Cryogenic Experts – more commonly known as CEXI – has been an industry leader since its founding in 1971.

Based in Oxnard, CA, CEXI was acquired by ACME Cryogenics of Allentown, PA, in 2019 and, by extension, became a product brand of OPW Clean Energy Solutions, Hamilton, OH, when OPW acquired ACME Cryogenics in 2021.