Skytree ‘pushing efficiencies to deliver DAC’ alongside other carbon moves

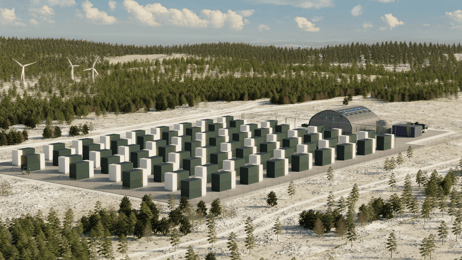

The opportunity in direct air capture (DAC) of carbon dioxide is reaching real maturity and from here should start scaling fast, just as other CO2 opportunities like biogenic also develop.

That was the message from Bjørn Utgård, Vice-President of Strategic Development at Skytree, the Amsterdam-based DAC company, who presented at the recent British Compressed Gas Association event in Manchester.

His stand-out comment was that the opportunity is certainly “hundreds of millions of tonnes per year, but most likely billions of tonnes of CO2 per year over the next few decades.”

One of the opening slides illustrated how Skytree’s technology works, explaining how “it’s basically like an ASU, except we don’t extract nitrogen but CO2.” Alongside concentrated CO2, some water is also captured from a sorbent, with more than half of its energy consumption is heating up the sorbent to release the CO2.

... to continue reading you must be subscribed