SLM Solutions Group using WITT technology

SLM Solutions Group AG is using WITT’s AV 919 safety relief valve to keep gas pressure constant during melting.

Optimal gas pressure in the process chamber is of enormous importance in the 3D printing process, during which metal is melted and formed into the required shape, the company explained.

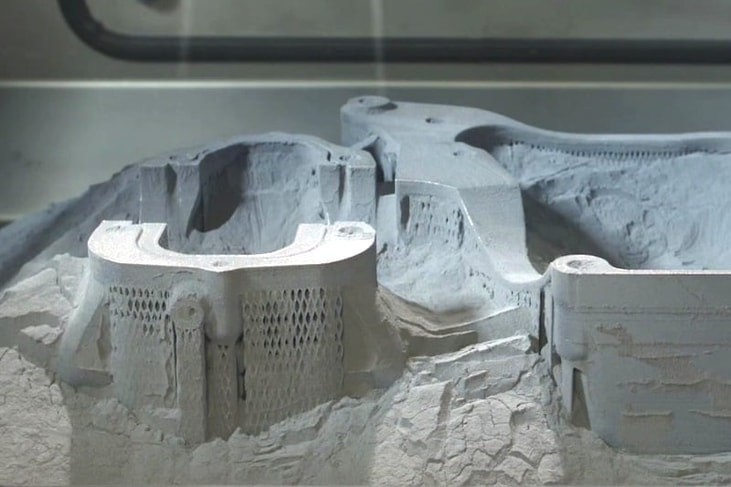

To handle metals in 3D printing, complex melting processes are needed: the material, e.g. stainless steel, cobalt, chrome or titanium is present in fine powder, that is melted layer by layer with high-performance lasers and built up to a final shape – called Selective Laser Melting.

SLM Solutions Group, headquartered in Lübeck, is a specialist in Selective Laser Melting and one of the leading manufacturers of 3D printers for metals. In their machines, the printing is executed under a protective gas atmosphere inside the process chambers. Moreover, the powder management, that is, the fully automated supply, removal and treatment of the metal powder retains this controlled atmosphere.

... to continue reading you must be subscribed