Sweden’s first biogas carbon capture plant to produce food-grade CO2

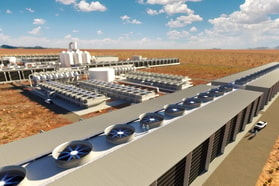

A new partnership between two European energy companies to install Sweden’s first carbon capture and utilisation (CCU) facility using biogas will produce 20,000 tonnes of food-grade carbon dioxide (CO2) per year.

Dutch clean energy firm Bright Renewables will supply CO2 liquefaction technology to Tekniska verken’s biogas plant Svensk Biogas in Linköping to purify and liquefy CO2 from the biogas production process.

Equipped with a capacity of 2.5 tonnes per hour of Bio-CO2, the liquefaction system includes technology to recover CO2 from the biogas upgrading process to purify and liquefy CO2 using a natural refrigerant.

... to continue reading you must be subscribed