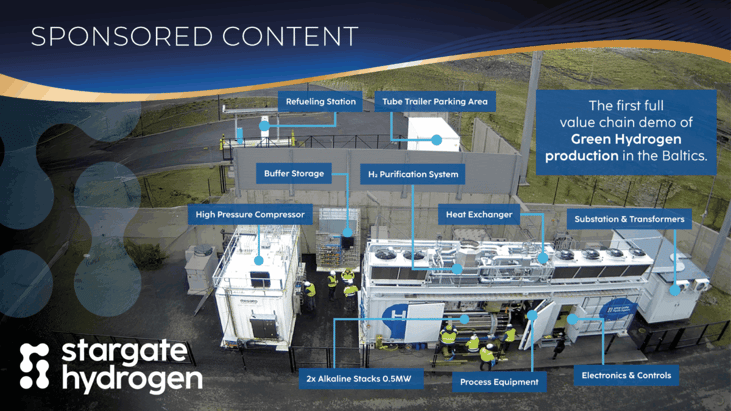

The Stargate Hydrogen story – from EU funding to full value chain delivery

Green hydrogen as an energy carrier sits at the heart of the global energy transition today.

Not every company that has moved on the opportunity in the past five years has delivered on their ambitions, which is always the case in new markets, but there are always breakthroughs to celebrate, and companies genuinely moving the dial on what’s possible.

One tangible success story is Stargate Hydrogen in Estonia, which since 2021 has been busy developing an advanced alkaline electrolyser that has a real claim to be revolutionary in reinventing what’s possible, with more improvements in the pipeline.

... to continue reading you must be subscribed